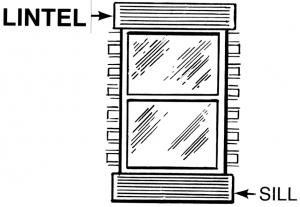

What Is A Lintel?

Do you need a lintel above a window?

In the case of a window, a lintel is extremely important since it distributes the weight of anything above the window onto the surrounding wall instead of placing the weight onto the window frame. Without a lintel above a window there is a danger of structural damage to a property.

Why should you install a lintel?

The reasons for installing a lintel are to replace a bad lintel or when installing a new window in a wall to provide additional support to the load above.

Spotting problems with lintels

The first signs of a problem with a lintel are usually cracks in the masonry above the windows and doors. Spotting a problem such as hairline or more serious cracks in concrete lintels are normally a sign the lintel should be replaced.

Whether you are replacing an existing lintel or starting from scratch when fitting a new lintel, care must be taken to prevent damage to the existing structure above and to the sides of the opening.

What are lintels made of?

Today, lintels are made of several different materials that are appropriate to the different compositions of walls in old as well as modern buildings. The materials which make up lintels include timber, concrete and steel. The material chosen for the lintel may depend on the load which the lintel will support.

Which Type Of Lintel Should You Choose?

When choosing a lintel, it is necessary to consider the wall type:

When choosing a lintel, it is necessary to consider the wall type:

- cavity

- timber frame

- exterior solid

- internal partition

- load bearing

It is also necessary when fitting a lintel to consider the type of load:

- roof trusses

- masonry

- floor joists

When deciding which material you should choose for your lintel consider the following points:

- A wood lintel is usually found in older homes and can be susceptible to dry rot and insects.

- Brick should never be used alone as a lintel, they are usually supported with flat steel.

- Stone is sufficient for a small span but is poor under tension.

- Concrete with steel rods running through for strength is a better choice than stone or brick.

- One of the easiest lintels to work with is pressed and galvanized steel, which is good for both brick and wood frame walls.

- If steel lintels are being installed they should have a minimum end bearing of 150mm. Steel lintels should be levelled and then bedded on mortar. Levelling should be carried out along both the length and the width of the lintel.

Image Attribution: Wikimedia Commons.

Is The Wall A Load Bearing Wall For My Lintel?

It is important, prior to the start of lintel installation work, to discover if the wall in question is a load-bearing wall.

This determination is done either by pulling up the floorboards to discover which way the joists run, or by consulting with a structural engineer.

Note that it is important to check the direction of the joists along the whole wall, since a common refurbishment includes trimmer joists, which distribute a new load such as a stairway.

Installing The Window Lintel

Step-by-step

- To install a new lintel, determine the size of the structural opening and add a minimum of 150mm to each end.

- Above the area of the lintel, install anchors and use acrow props to support wall as you remove masonry for the lintel.

- Use a hammer and chisel to remove mortar around the bricks to be removed.

- Once the mortar is removed, remove the bricks to make room for the new lintel.

- A bed of mortar should be laid and the lintel installed.

- The mortar needs to cure for at least two days before any other work can be done in the area of the new lintel.

Drilling into lintels

Lintels are tough so if you need to drill into them you should consider using an SDS drill and drillbits.

Building Regulations, Professional Advice And Lintels

It is important to note that installing a lintel involves structural work that may need approval from the building authority.

Your local planning portal will likely be able to advise you on regulations around installation of lintels to window and door frames.

The circumstances, weight of the load and whether the wall is a load bearing wall in the first place may all have a bearing on the restrictions and the need for authorisation required.

Moreover, determining whether a wall is load bearing can be tricky and it is certainly worth getting a professional opinion.

10 Frequently Asked Questions About Installing a Lintel Above a Window

Below are the most frequently asked questions about installing lintels—answered clearly and accurately.

1. What is a lintel, and why do I need one above a window?

A lintel is a horizontal support (often made of steel, concrete, or timber) placed above an opening such as a window or door. Its purpose is to:

-

Bear the load of the masonry or structure above

-

Distribute the weight around the opening

-

Prevent cracking or sagging in the wall above

Without a lintel, the window or door frame could fail, or worse, the wall could collapse over time.

2. How do I know if I need to install or replace a lintel?

You may need a new lintel if:

-

You’re creating a new window or door opening

-

The existing lintel is damaged, cracked, or bowing

-

There are visible cracks in the brickwork or plaster above the window

-

You're replacing old timber lintels that have deteriorated

If in doubt, consult a structural engineer or builder for advice.

3. Do I need building regulations approval to install a lintel?

Yes.

In the UK, installing or altering a lintel is classed as structural work and falls under Building Regulations. You’ll need to:

-

Notify your local authority or use a competent person scheme

-

Possibly provide structural calculations if it’s a major alteration

Failing to get approval can cause problems when selling your property.

4. What types of lintels are available?

Common types include:

-

Concrete lintels – cost-effective and widely used in load-bearing walls

-

Steel lintels (e.g. Catnic or IG) – lightweight, corrosion-resistant, used in cavity walls

-

Timber lintels – used in older buildings, but rarely used in modern construction

-

Stone or brick arch lintels – decorative and structural in heritage buildings

The right type depends on wall construction, load-bearing requirements, and aesthetic preferences.

5. How do I choose the correct size of lintel?

The correct size depends on:

-

The span (width of the window or door)

-

The load above the opening (wall height, roof, floors)

-

The wall construction (single skin, cavity, etc.)

As a general rule:

-

The lintel should extend 150mm past each side of the opening

-

Use a structural lintel calculator or consult a builder or engineer for accurate specs

Manufacturers like Catnic or IG offer load charts to help with sizing.

6. Can I install a lintel myself?

You can—if you have:

-

Good DIY experience and basic bricklaying skills

-

Proper tools: acrow props, strongboys, angle grinder, level, etc.

-

Knowledge of how to support the wall safely during installation

However, for structural work or in load-bearing walls, it’s safer to hire a qualified builder or seek professional advice.

7. How is a lintel installed above a window?

Typical steps include:

-

Support the wall above the opening with acrow props and strongboys

-

Remove a section of brickwork above the window to create space for the lintel

-

Insert the lintel, ensuring a minimum 150mm bearing at each end

-

Use slate packers and mortar to level and bed the lintel

-

Rebuild the brickwork above and allow the mortar to cure

-

Remove supports only when the structure is stable

Always follow the lintel manufacturer’s installation guidelines.

8. What is a cavity wall lintel, and when is it used?

A cavity wall lintel is a specially shaped lintel designed for walls with two layers (an inner and outer skin, separated by a cavity).

It usually:

-

Has a horizontal flange to support the outer skin

-

Comes with built-in insulation to reduce thermal bridging

Use cavity lintels in modern properties with cavity walls, especially above windows and doors in external walls.

9. Can I install a lintel above a uPVC or timber window frame?

Yes. In fact, you must.

Window frames aren’t designed to carry structural loads, so a lintel is required above all types of windows, including:

-

uPVC

-

Timber

-

Aluminium

-

Composite

Even if the frame appears to be holding the load, cracks or movement will likely occur over time without a proper lintel.

10. How much does it cost to install a lintel above a window?

Typical costs (UK prices):

-

Materials only (steel or concrete lintel): £30–£120

-

DIY installation: £30–£150 (excluding tools)

-

Professional installation: £250–£600+, depending on wall type, access, and if brickwork needs replacing

Costs can rise for wider spans, cavity lintels, or more complex jobs involving structural engineers.

🔧 Final Advice

Installing a lintel isn’t just about fitting a beam—it’s about safely supporting the structure of your home. If you’re unsure of the load, wall type, or installation method, always consult a professional. Structural safety should never be guessed.